Burgeoning Demand for Aluminum–Scandium Alloys in Aerospace & Defense Sector Drives Global Scandium Market Growth

According to the latest market study on “Global Scandium Market Analysis and Forecast to 2031 – Global Analysis – by Derivative and Application," the market was valued at US$ 230.26 million in 2023 and is projected to reach US$ 1,660.13 million by 2031; it is estimated to register a CAGR of 28.0% from 2023 to 2031. The report highlights key factors fueling the market growth and prominent players along with their developments in the market.

Scandium, a rare earth element, was included in the list of Critical Raw Materials (CRM) in 2017 by the European Commission (EC). It is a transition metal used in the production of solid oxide fuel cells and high-strength alloys that are used in aerospace and 3D printing applications, respectively. Scandium is found in less quantities in monazite. It is economical to extract scandium from uranium tailings, thortveitite, euxenite, and gadolinite. Scandium also coexists in minute quantities in iron, molybdenum, aluminum, cobalt, nickel, titanium, tungsten, zinc, and zirconium ores. The global scandium market size is likely to upsurge by 2030 owing to the advancements in extraction and processing methods.

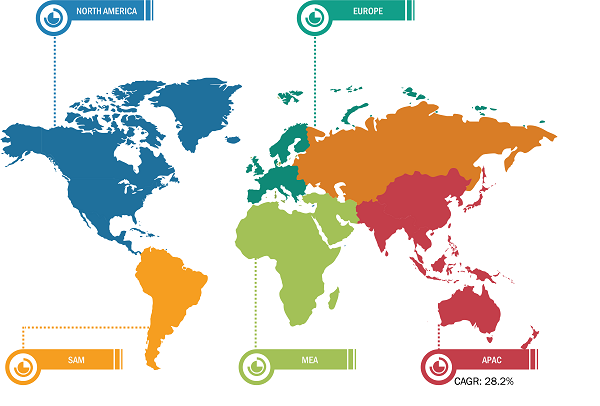

Global Scandium Market Breakdown – by Region

Scandium Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Derivative (Oxide, Iodide, Alloy, Zirconia, and Others) and Application (Aerospace and Defense, Solid Oxide Fuel Cells, Electronics, Ceramics, Lighting, Nuclear Applications, 3D Printing, and Others)

Scandium Market Size, Share, Growth & Scope | Analysis 2031

Download Free Sample

The increasing adoption of solid oxide fuel cells propels the scandium market growth. Solid oxide fuel cells (SOFCs), known for their high efficiency and low emissions, are gaining traction as a promising alternative to conventional power generation technologies in various sectors, including stationary power generation, transportation, and portable electronics. Scandium plays a pivotal role in SOFC technology, particularly in the form of scandium-stabilized zirconia (ScSZ). Used as an electrolyte in these cells, ScSZ improves ionic conductivity at elevated temperatures, enabling efficient ion transport across the cell and enhancing overall performance. This results in higher energy conversion efficiencies and enhanced durability, making SOFCs more attractive for widespread commercial and industrial applications. The surging demand for clean energy owing to environmental concerns and regulatory pressure to reduce greenhouse gas emissions is fueling the adoption of SOFCs worldwide. SOFCs, when operated with a hydrocarbon fuel source, generate CO2, but they carry out much cleaner processing of fuels than combustion-based systems, positioning themselves in low-emission devices. In 2000, the US Department of Energy initiated the SOFC Program to develop low-cost, highly efficient, environmentally friendly SOFC technology for smaller, modular-scale, large-scale power generation from natural gas or coal-derived synthesis. Thus, the increasing adoption of solid oxide fuel cells contributes to the growing scandium market size.

The surging popularity of electric vehicles is likely to bring new scandium market trends in the coming years. Lightweight and high-performance materials help improve the efficiency and range of electric vehicles (EVs). As the automotive industry experiences a transformative shift toward electric vehicles, scandium's role becomes even more pronounced. The strength of scandium–aluminum alloys makes it an attractive choice for EV manufacturing. In the automotive sector, wherein reducing weight is paramount for optimizing energy efficiency and extending battery performance, scandium–aluminum alloys are used in vehicle components such as body panels, chassis, and battery enclosures; this allows automakers to achieve significant weight reductions without compromising structural integrity. This results in lighter and more energy-efficient EVs that can travel longer distances with a single charge, thus addressing key consumer concerns. Scandium-containing materials, such as scandium-doped aluminum electrodes, have shown promise in improving battery conductivity and stability, leading to faster charging times, higher energy density, and increased longevity. These advancements contribute to the overall competitiveness of EVs by improving their driving range and reducing charging times, thereby accelerating their adoption in the marketplace. The electrification of the automotive sector is driving demand for efficient power electronics and electric motor systems, where scandium-based materials can play a crucial role. Scandium-containing semiconductors exhibit superior electrical conductivity and thermal stability, making them well-suited for EV power electronics applications such as motor controllers, inverters, and onboard charging systems.

Scandium International Mining Corporation, American Elements Inc, NioCorp Development Ltd, Strategic Metal Investments Ltd, Rio Tinto, US Research Nanomaterials Inc, Otto Chemie Pvt Ltd, Stanford Advanced Materials, Heeger Materials Inc, and Hunan Oriental Scandium Co Ltd. are among the prominent players profiled in the scandium market report. In addition, several other players have been studied and analyzed during the study to get a holistic view of the market and its ecosystem. The market report also includes company positioning and concentration to evaluate the performance of competitors/players in the market.

The scandium market report aims to provide an overview of the market with detailed market segmentation. The market is segmented on the basis of derivative and application. Based on derivative, the market is segmented into oxide, iodide, alloy, zirconia, and others. The oxide segment accounts for the largest scandium market share. Scandium oxide (Sc2O3) appears in the form of a cubic crystal lattice, providing it with remarkable thermal stability and mechanical strength. Scandium oxide finds extensive application in the production of advanced ceramics and refractory materials. When added to ceramic formulations, it enhances mechanical properties such as strength and toughness, and thermal shock resistance. These properties also make scandium oxide the material of choice in industries such as aerospace, wherein components and devices must withstand extreme conditions. Due to their large surface area and unique surface chemistry, scandium oxide nanoparticles have emerged as crucial components in catalysis. They are used as effective catalysts in various chemical reactions, including organic synthesis and environmental remediation processes. Further, the optical properties of scandium oxide make it useful in optics and electronics. As a dopant in glass and semiconductor materials, it modifies their electronic band structure and optical properties, enabling applications in laser technology, phosphors, and high-performance electronics.

Based on application, the scandium market is segmented into aerospace and defense, solid oxide fuel cells, electronics, ceramics, lighting, nuclear applications, 3D printing, and others. The aerospace and defense segment accounts for the largest scandium market share. In the aerospace industry, the most common form of scandium used is scandium–aluminum alloys. These alloys offer a remarkable combination of strength, stiffness, and corrosion resistance while remaining lightweight, rendering them a material choice in the production of aerospace components such as aircraft frames, wings, and engine parts. The addition of scandium enhances the mechanical properties of aluminum alloys, allowing for the design of lighter and more fuel-efficient aircraft without compromising structural integrity. In the defense industry, scandium alloys are utilized in the production of lightweight armor and ballistic protection systems. By incorporating scandium into armor materials, manufacturers can produce protective gear that offers superior protection against ballistic threats while minimizing weight and bulkiness. These abilities of scandium-based materials are particularly crucial for military personnel and vehicles where mobility and agility are paramount. Scandium also finds applications in advanced propulsion systems and aerospace components. Scandium-containing materials are used in rocket engine components, where their high temperature resistance and mechanical strength ensure reliable performance in extreme environments. Scandium–aluminum alloys are also employed in the construction of aerospace components subjected to high temperatures and corrosive conditions, such as exhaust systems and heat shields. Moreover, scandium's use extends to electronic systems, circuitry technologies, and sensors employed in aerospace and defense applications, where their electrical and thermal conductivity properties contribute to improved performance and reliability.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com